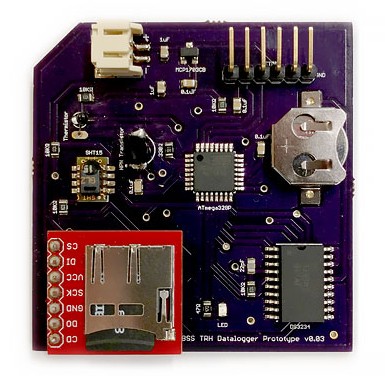

We’ve been testing several wireless prototypes of building sensor nodes and will keep this blog updated on the progress as we go along. In the meantime, we thought it would be cool to make a PCB version of our T/RH data logger. The board was designed in CadSoft Eagle and sent over to OSH Park for fabrication. Here’s is one of the OSBSS data logger prototypes that we soldered (using a hacked $12 toaster oven from Target, obviously):

Now this is by no means bug-free or the final version – it will be going through many design changes till it’s stable enough. We will also drop all breakout boards and through-hole components and switch to using SMD components (where applicable). We are also testing other MCUs, sensors, components and board layouts. However this serves as a proof of concept for a robust offline data logger than can last a year (more, depending on your logging interval) on a single battery and store unlimited data. In comparison to our T/RH data logger on a solderable breadboard which takes around 1-2 hours to fully assemble (provided you didn’t do any mistakes – which take additional time to find and fix), assembling, soldering and having this PCB up and running took about 20 mins. That time can certainly be lowered once you start creating boards in several batches. We will be making the boards much smaller – hopefully around the size of Arduino Pro Minis themselves.

We will be converting these into wireless boards – the RFM69 is a great transceiver to start with and we’ve successfully tested several wireless node prototypes based on the famous Moteinos from LowPowerLab which send all building environment data to a gateway and upload the data to an online database. The gateway will also have all data backed up to a microSD card for redundancy. From the next generation of OSBSS data loggers, expect more features, lower current draw, better performance and best of all – cheaper price. More info coming soon.

Side note: For those who don’t know about OSH Park – they manufacture PCB boards and are based in USA. They charge as low as $5 per sq. inch. (with free shipping worldwide), which for small volume prototype testing, is fair for the quality of their boards. Speaking of quality – theirs is impeccable, near perfect, and their purple solder mask makes all boards look very unique, even if it’s a simple one. A cool thing about OSH Park: they barely advertise and they rely on the word of mouth and the online community for their services to be known. One disadvantage would be that despite being based in the US, their delivery time is around 9-10 days, sometimes up to 2 weeks or more. While this is lower compared to some Chinese board manufacturers (which generally take around 4 weeks or more), it would have been nice to have something under a week. However, the founder of OSH, Park James Neal, sets up these neat panalization scripts and algorithms to arrange the board designs in large panels and he does that all by himself, making sure the quality of each and every board is accounted for, and I’d rather wait two weeks knowing I’m getting a high quality board than waiting four weeks and finding out my “cheaper” boards have incorrect traces or damaged solder mask. Definitely gets our recommendation for small volume PCB prototyping.